Professional Sharpening Service

1: Book An Appointment

Complete the online form or call us to schedule an appointment time that is convenient for you.

2: Appointment Confirmation

You will receive a call or a confirmation email about your booking for any additional information needed or details about the visit.

3: Pickup

My sharpening specialist will arrive at the pick up location you specified and discuss with you and answer all your questions and collect your knives or other tools for transport.

4: Delivery

Your knives and / or tools will be delivered back to you at the time specified where payment will be collected.

5: Optional

You can also drop off your knives and / or tools with me at the farmers market on Saturday and have me deliver them or collect them at the next market day. Get with me for details.

Why Choose My Sharpening Service?

- Professional Sharpening: My Sharpeners will sharpen your knives and tools on professional sharpening tools designed for industrial and precision use.

- Convenience: Bring them to me or one of my sharpeners at the local Farmers Market or have me or one of my sharpeners come to you.

- No hidden fees: $25 for a pickup and delivery or $15 for a delivery or a pickup, No charge for pick up and dropping off at the Farmers Market. Most tools have a set fee with knives calculated by the inch with a 3 inch minimum. See my price list for specifics

- Reliable Service: My goal is 100% satisfaction with every sharpening, and if I can’t do it then its likely time for a new tool/knife, and I will tell you as much before hand.

How We Sharpen

Experience, Quality Craftsmanship and Attention to the details makes all the difference! Myself and my employee’s have a passion for knife making and have made custom knives for years. Our workshop has the tools and we have the know how to get the job done right the first time this makes us the trusted choice to sharpen your knives or anything else that needs a professional done sharp edge.

Each knife is unique

We know knives! Your knife will be sharpened

with the best treatment according to its

individual material, design and anatomy,

including any existing damage to the blade.

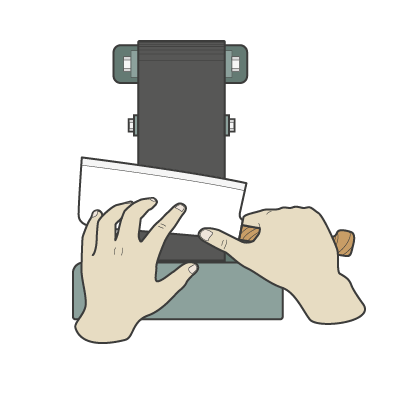

Always done by hand

The main sharpening process is always done by hand on air-cooled ceramic belts. For re-profiling, repairs, thinning and re-beveling, we use different techniques for different kinds of knives and their varying angle requirements.

Getting the angle right, a truly bespoke approach

Western style Japanese knives

(SHUN, GLOBAL, TOJIRO, ETC)

• 10-16 degrees depending on steel quality and kind of grind

• Sharpened as above, with the addition of two or more finer belts

• Deburring and polishing on leather belt with compound

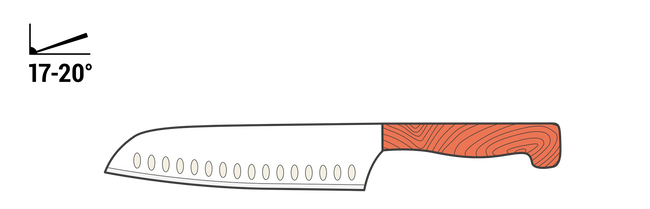

German and other non-Japanese knives (WUSTHOF, VICTORINOX, CUISINART, ETC.)

• 17-20 degrees on the final edge, depending on the quality and type of knife

• Sharpened on ceramic belts or structured abrasive belts for a polished, but slightly toothy, long lasting edge

• Deburring (taking off small, loose metal shavings) and finishing on hard felt wheels with compound

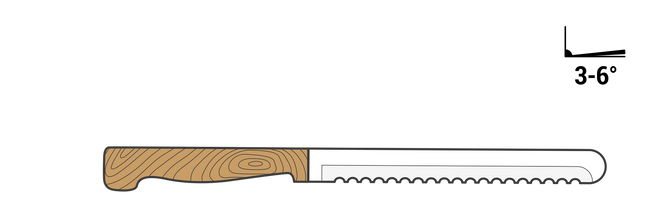

Serrated knives

• 3-6 degrees on their flat side for really sharp serration tips

• Sharpened on fine ceramic belts or structured abrasive belts

• Deburring and polishing on super fine scotch brite belts for smaller serrations and leather belts for bigger serrations as in bread knives

Ceramic knives

• Sharpened on a proprietary, watercooled diamond flex-wheel setup, similar to the capping wheels used to shape and polish stones and crystals

• Finished and polished using diamond paste on a lapping wheel

For the knife nerds...

No slacking allowed

We sharpen on the platten instead of a slack belt to maintain a straight bevel – as opposed to creating a convex edge. This also protects the heel and tip of your knives from being ‘rounded off.’

Through thick and thin

To guarantee your knives perform at their best, we always consider the thickness behind the edge when sharpening. For most knives, the blade is supposed to be as thin as possible (exceptions apply).

Quality control

Before we send your newly sharpened knives back to you, each knife will undergo a quality control procedure on our proprietary testing paper for both slicing and cutting.

![004[1] 004[1]](https://jrkknives.com/assets/uploads/elementor/thumbs/0041-r1w3cax4g71kcsoxc24jptg1srxxbc5ke4o6ztdjug.png)

Getting gritty

We use between 120 and 2,500 grit size. For a nice polished edge when needed, we buff on jewelers rouge, which is comparable to a grit size of about 15,000. Deburring and polishing on a leather belt with compound gives an even slicker, more polished edge. It is all about the perfect compromise between slicing and cutting performance, combined with longevity of the edge, and it all depends on the knife in our hands.

100% customer satisfaction guarantee

You will love the way your knives feel when they come back from us! If you are not 100% satisfied, we will resharpen your knives for free.